Parcours de croissance de Landpower : Aperçu d’un exportateur mondial de premier plan de systèmes de montage solaire lestés pour toitures plates

Nov 19, 2025

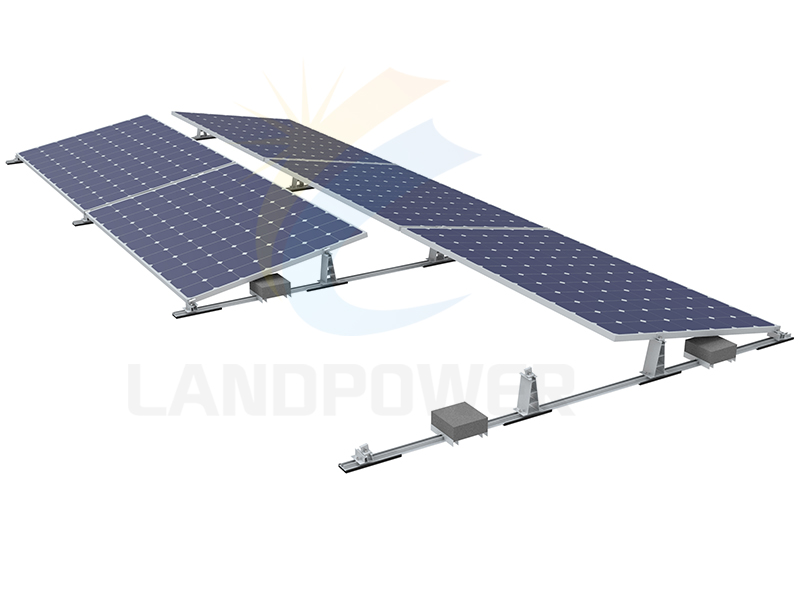

Parcours de croissance de Landpower : Aperçu d’un exportateur mondial de premier plan de systèmes de montage solaire lestés pour toitures platesSur le marché solaire actuel, en pleine expansion, une question cruciale détermine le succès : qui possède réellement l’expertise et le savoir-faire industriel nécessaires pour servir de leader ? premier Leader mondial du ballast Installation de panneaux solaires pour toiture plate ExportateurLe marché des systèmes de montage solaire pour toitures plates devrait atteindre 23,2 milliards de dollars américains d'ici 2033., Portée par un taux de croissance annuel composé remarquable de 12,5 %, la réponse réside sans équivoque dans la maîtrise des deux aspects par les entreprises. avant-gardiste innovation technique et robuste distribution mondiale. Xiamen Landpower Solar Technology Co., Ltd. témoigne de cette évolution, passant d'un fabricant local à une force internationale en 12 ans de service dévoué.L'essor des solutions de montage lestées : les forces du marché en jeuLe marché du solaire commercial connaît une évolution sans précédent vers les systèmes de montage lestés, grâce à leurs avantages uniques pour les toitures plates. Ce marché, estimé à 2,5 milliards de dollars en 2025, devrait afficher un taux de croissance annuel composé (TCAC) de 12 % entre 2025 et 2033, pour atteindre une valeur estimée à environ 7,5 milliards de dollars d'ici 2033. Cette croissance fulgurante s'explique par plusieurs facteurs convergents qui favorisent les méthodes d'installation sans perforation.Toit plat lesté solaire Les systèmes solaires à toiture plate lestés ont gagné en popularité car ils éliminent les perforations de toiture, simplifiant ainsi l'installation et préservant les garanties du bâtiment. Ce type de montage ne nécessite aucune perforation, ce qui le rend particulièrement intéressant pour les propriétaires d'immeubles commerciaux soucieux de l'intégrité de leur toiture et des questions d'assurance.La polyvalence des systèmes lestés dépasse le cadre des applications traditionnelles. Le système de montage solaire à lestage non pénétrant pour toitures plates peut facilement être utilisé comme système de montage photovoltaïque au sol, offrant ainsi aux installateurs des solutions flexibles qui s'adaptent aux exigences de divers projets.Évolution stratégique de Landpower : d’innovateur local à exportateur mondialAyant très tôt compris les dynamiques du marché, Landpower s'est positionnée stratégiquement sur le segment des systèmes de montage lestés. Fabricant OEM professionnel de systèmes de montage solaire lestés en Chine, Landpower propose depuis plus de 12 ans une gamme complète de solutions de montage pour toitures plates. Cette vaste expérience a permis à l'entreprise d'optimiser ses produits et ses processus, tout en développant l'échelle de production nécessaire à son expansion internationale.Le parcours de l'entreprise reflète les grandes tendances de la fabrication de panneaux solaires en Chine, où l'expertise technique se conjugue à une efficacité de production optimale pour répondre aux besoins des marchés mondiaux. Nos systèmes de montage sont installés avec succès dans une cinquantaine de pays à travers le monde, témoignant de la réussite de Landpower dans sa transition d'une activité nationale à une présence internationale.Les principaux avantages concurrentiels à l'origine du succès internationalQu'est-ce qui distingue Landpower en tant que Fournisseur de systèmes de montage solaire lestés pour toitures plates Il ne s'agit pas seulement de leur capacité de production, mais aussi de leur approche systématique pour relever les défis complexes liés à l'installation :Excellence en ingénierieDepuis sa création, Landpower accorde une grande importance à l'innovation et au développement de solutions répondant à diverses normes internationales et conditions environnementales. Nos systèmes lestés font l'objet d'analyses d'ingénierie rigoureuses afin de garantir leur intégrité structurelle face à des charges de vent variables et aux exigences sismiques.Sophistication de la fabricationLandpower est synonyme d'excellence dans le traitement des métaux, grâce à des capacités de production garantissant une qualité constante à grande échelle. Cette excellence manufacturière lui permet de servir efficacement aussi bien les équipementiers que les marchés de la vente directe.Portefeuille de solutions completAu lieu de se concentrer uniquement sur les systèmes lestés, Landpower propose des solutions de montage intégrées. Nous développons et fabriquons des solutions de montage pour les centrales solaires, les toitures plates, les toitures inclinées et les abris solaires pour véhicules, offrant ainsi à nos clients une solution unique pour leurs projets complexes.Applications du produit : Répondre à divers besoins commerciauxLes systèmes de montage lestés pour toitures plates de Landpower desservent de multiples segments commerciaux, chacun présentant des exigences techniques uniques :Installations dans les bâtiments commerciauxLes grands centres commerciaux, les entrepôts et les immeubles de bureaux constituent les principaux marchés des systèmes lestés. Ces applications bénéficient d'une conception sans perforation qui préserve les garanties de toiture tout en permettant d'importantes augmentations de la capacité solaire.Installations industriellesLes usines et les centres de distribution nécessitent des solutions de montage capables de résister aux environnements industriels, aux vibrations des équipements lourds et aux variations de température. Les systèmes lestés de Landpower offrent la stabilité requise pour ces applications exigeantes.Projets institutionnelsLes écoles, les hôpitaux et les bâtiments gouvernementaux imposent souvent des installations non pénétrantes afin de préserver l'intégrité des bâtiments et de se conformer aux exigences strictes en matière de gestion des installations. Cette approche par lestage s'inscrit parfaitement dans les politiques institutionnelles de gestion des risques.Aménagements à usage multipleLes projets commerciaux à usage mixte bénéficient de la flexibilité des systèmes lestés, permettant des installations solaires qui s'adaptent aux différentes configurations de toiture et aux exigences de charge des différents types de bâtiments au sein d'un même projet.Témoignages de réussite client : Excellence de la mise en œuvre à l’échelle mondialeLa croissance internationale de Landpower témoigne de la réussite de ses projets sur divers marchés et pour diverses applications. Landpower a conçu et fourni une large gamme de systèmes de montage photovoltaïques innovants et de haute qualité pour les clients résidentiels, commerciaux et les grandes centrales électriques, démontrant ainsi sa capacité à répondre aux besoins de projets allant des petites installations commerciales aux grands aménagements.Leur succès à l'export repose sur leur compréhension des spécificités des marchés régionaux. Les marchés européens privilégient les certifications techniques et la durabilité environnementale, tandis que les marchés émergents se concentrent sur le rapport coût-efficacité et la simplicité d'installation. La capacité de Landpower à adapter ses solutions aux exigences régionales spécifiques lui a permis de s'implanter sur de nombreux marchés internationaux.La diversité de leur portefeuille de projets témoigne de leur polyvalence technique. Des climats tropicaux exigeant une résistance accrue à la corrosion aux régions nordiques nécessitant une capacité de charge de neige élevée, les systèmes lestés de Landpower ont démontré leur performance dans des conditions environnementales extrêmes.Trajectoire d'innovation : progrès technologique et adaptation au marchéLe succès continu de Landpower repose sur l'innovation technologique qui anticipe l'évolution du marché. Les développements actuels se concentrent sur plusieurs axes clés :Optimisation de la chargeLes techniques d'ingénierie avancées permettent de réduire les besoins en ballast tout en maintenant les performances structurelles, en diminuant les coûts de transport et en simplifiant les procédures d'installation.Conception modulaireDes composants standardisés, combinés en configurations personnalisées, permettent une fabrication efficace tout en offrant des solutions adaptées à chaque projet.Efficacité de l'installationLes améliorations de conception qui réduisent le temps d'installation et les besoins en main-d'œuvre permettent de pallier la pénurie de main-d'œuvre qualifiée qui touche l'industrie solaire à l'échelle mondiale.Performance environnementaleDes matériaux et revêtements améliorés qui prolongent la durée de vie du système tout en maintenant des prix compétitifs contribuent à la rentabilité à long terme des projets.Positionnement sur le marché et perspectives d'avenirLa convergence de politiques gouvernementales favorables, de la baisse des coûts de l'énergie solaire et de l'engagement croissant des entreprises en matière de développement durable crée un contexte propice aux fournisseurs de systèmes de montage lestés. Le marché des systèmes de montage photovoltaïques devrait connaître une forte croissance dans les années à venir, pour atteindre 36,61 milliards de dollars en 2029, avec un taux de croissance annuel composé (TCAC) de 6,3 %.Le positionnement de Landpower dans cette trajectoire de croissance témoigne d'une vision stratégique et d'une efficacité opérationnelle remarquables. Son expertise en matière de systèmes lestés répond aux attentes du marché pour les installations non pénétrantes, tandis que ses capacités d'exportation lui permettent de participer à l'expansion du marché mondial.L'engagement de l'entreprise envers la qualité et l'innovation lui permet de tirer profit des opportunités émergentes sur les marchés en développement où l'adoption de l'énergie solaire s'accélère. fournisseur de systèmes de montage solaire lestés pour toitures plates Forte d'une expérience internationale éprouvée, Landpower possède l'expertise technique et la capacité de production nécessaires pour soutenir une croissance continue du marché.Partenariats stratégiques et distribution mondialeL'expansion internationale exige bien plus que des produits de qualité : elle requiert des partenariats fiables et des réseaux de distribution performants. Le succès de Landpower témoigne de sa capacité à nouer des relations avec des distributeurs, des installateurs et des intégrateurs de systèmes sur de nombreux marchés.Leurs capacités en matière de fabrication à façon permettent de nouer des partenariats de marque privée avec des marques régionales, élargissant ainsi leur présence sur le marché tout en tirant parti de leur connaissance du marché local. Cette approche s'est avérée particulièrement efficace sur les marchés où les relations établies et la présence locale constituent des avantages concurrentiels.Maintenir le leadership grâce à une évolution continueLa transformation de Landpower en une Exportateur mondial leader de systèmes de montage solaire lestés pour toitures plates Ce parcours illustre comment l'expertise technique, l'excellence de la production et la connaissance du marché s'allient pour créer des avantages concurrentiels durables. Leur évolution en douze ans, d'un fabricant local à un fournisseur international, démontre le potentiel des entreprises spécialisées dans le solaire à atteindre une envergure mondiale.Alors que le secteur solaire poursuit son expansion rapide, des entreprises comme Landpower, qui allient compétences techniques éprouvées et expérience opérationnelle internationale, joueront un rôle crucial dans le déploiement mondial de l'énergie solaire. Leurs solutions de montage lestées répondent aux besoins réels du marché, tandis que leurs capacités d'exportation permettent de participer à l'adoption mondiale de l'énergie solaire.Pour plus d'informations sur les solutions complètes de montage lesté pour toitures plates de Landpower et ses capacités de distribution mondiales, veuillez consulter le site web suivant : https://www.landpowersolar.com/